Minimum der Bestellmenge:1 Piece/Pieces

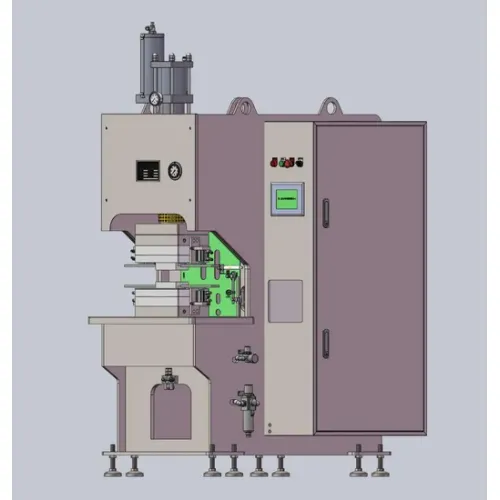

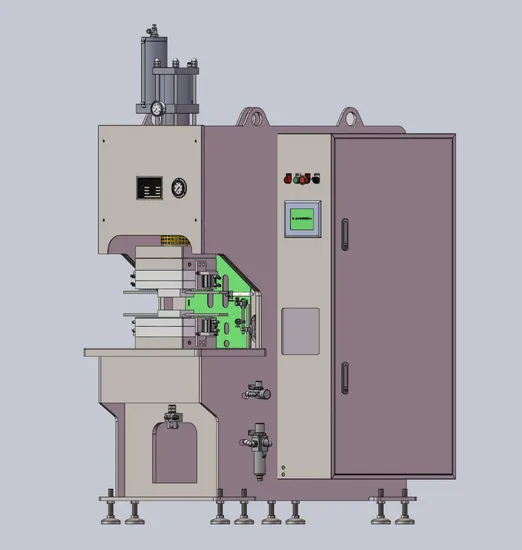

Style: Vertical

Shielding Gas: No

Electric Current: DC

Type: Diffusion Welding Machine

Transport Package: at Customer's Requrest

Specification: export standard

Trademark: xinchang

Origin: Ningbo China

HS-Code: 84688000

Produktionskapazität: 100 Sets/Month

Anpassung: Available

Cooling Way: Water Cooling

Control: Semi-Automatic

Unterstützung über: 100 Sets/Month

Merkmale:

Die Polymerdiffusionsschweißmaschine wird in zwei Typen unterteilt: Kupferschweißmaschine und Aluminiumschweißmaschine. Es handelt sich um eine spezielle Schweißmaschine für die Herstellung von New-Energy-Fahrzeugen, Power-Batterie-Soft-Verbindungen und Power-Soft-Verbindungen. Die Vorteile liegen darin, dass kein Lötmittel erforderlich ist, dass spurlos geschweißt werden kann und dass das Werkstück glatt aussieht. Die Produkte werden häufig in Fahrzeugen mit neuer Energie, Energiebatterien, Schaltschränken, Transformatoren, Energieinstallationen und anderen Branchen eingesetzt. Die von unserem Unternehmen unabhängig entwickelte und produzierte Polymerdiffusionsschweißmaschine ist auf dem führenden Niveau in China. Das Produkt wird seit vielen Jahren von vielen Unternehmen der Branche normal verwendet und genießt gute Benutzerbewertungen und einen guten Ruf bei inländischen Herstellern von Schweißgeräten.| 1 | Suitable for soft aluminum sheets welding, also capable of surface nickel welding, copper-aluminum welding, aluminum-aluminum welding. |

| 2 | Heating temperature:≥800ºC,Temperature measurement range:300ºC-1400ºC,Process accuracy:±3. Temperature, pressure, time, etc. can be adjusted and displayed on the touch screen . |

| 3 | The equipment mainly uses gas-liquid booster cylinders and precision pressure regulating valves to control the pressure to achieve the product welding process thickness tolerance requirements.. |

| 4 | Graphite installation area:130*80*70mm |

| 5 | Effective welding area:100*100mm (The product requirements of larger welding area can be achieved through segmented welding) |

| 5 | Electrode installation area:140mm*90mm |

| 6 | Welding material thickness:0.03mm-5mm |

| 7 | Welding product thickness:0.5mm-25mm |

| 8 | Cooling water requirements: The water flow rate requirement is 12m³/h, the head is 20 meters, or an equivalent booster pump can meet the mass production needs. Cooling water requirements:

|

| 9 | Aluminum foil meets batch single-piece peel strength≥3N/mm² |

| 10 | Digital hydraulic cylinder pressurization, max output pressure 10T,starting pressure 50KG,adjustment step unit 10Kg,set pressure accuracy within ±5% FS,welding accuracy ±0.1mm. Welding stability is determined by sir pressure. |

| 11 | C type vertical welding table |

| 12 | Power wiring:≥70mm2 Copper core wire, three-phase five-wire system. Incoming power requirements:

|

| 13 | High frequency heating, rated power 100KVA |

| 14 | Noise level below 65 decibels |

| 15 | Grey, close to RAL9010 paint |

| 16 | 1,The equipment is equipped with safety devices during operation, which can put the system into grounding state in any abnormal operation to ensure no high voltage load. 2,There are no obvious sharp parts on the outside of the device to prevent injuries to people during use. 3,Parts of the equipment that pose safety risks should be clearly marked, such as anti-electric shock sign and warning sign. 4,The equipment has the function of water temperature, water flow, current, voltage, and phase loss abnormal alarm and shutdown protection. |

| 17 |

3. The equipment must not misappropriate the protected patent technology of a third party. Party B shall be responsible for any disputes arising therefrom, and Party A shall not be responsible. |

| 18 | The equipment has functions such as quick release, quick change, graphite fixture, etc. |

1.F: Wie sieht es mit Ihrem Standardlieferdatum aus?

1.F: Wie sieht es mit Ihrem Standardlieferdatum aus?