Minimum der Bestellmenge:1 Piece/Pieces

Modell Num.: SKCKW40-R1

Anwendung: Metal

Process Usage: Cnc Non-Conventional Machine Tools

Movement Method: Linear Control

Numerical Control: NC

Processing Precision: 0.05~0.06(mm)

Performance Classification: Mid-Range CNC Machine Tools

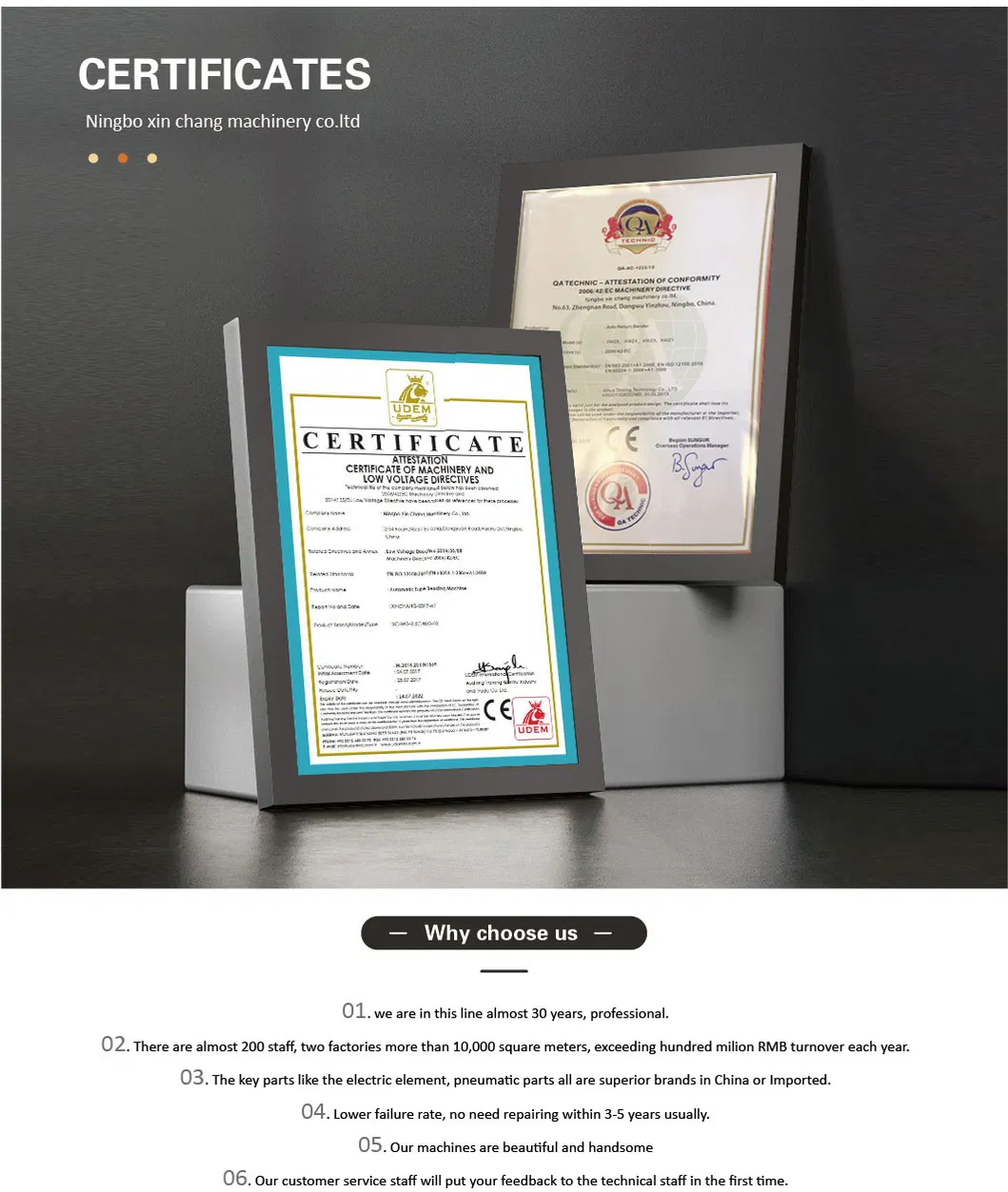

Zertifizierung: Ce, Iso 9001

Bedingung: Neu

Name: Hole Punching Machine

Key: Bending Machine

Bending Mode: by Servo Motors

Stroke Setting Model: by Servo Motors

Transport Package: Wooden Case

Trademark: Xin chang

Origin: Ningbo

Produktionskapazität: 100set/ Year

Anpassung: Available

After-sales Service: Life Long

Garantie: 12 Monate

Unterstützung über: 100set/ Year

| Model | SKCKW40-R1 |

| Bending range (diameter × wall thickness mm) | Φ12-φ40×1.5 (copper pipe) |

| Mould direction | Right bending |

| Bending radius | R 20-100mm (at center line) |

| Workpiece length | Active type: 100-1,200mm, through type: 100-1,800mm; |

| Straight feeding stroke (Axis X) | 0--1200mm Speed:0--500mm/sec, Precision: ±0.05mm |

| Spatial rotation angle (Axis Y) | 0--±360° Speed:0--300°/sec Precision: ±0.05° |

| Bending angle (Axis Z) | 0--200° Speed:0--180°/sec Precision: ±0.05° |

| Minimum processed pipe diameter for punching | Φ12mm*0.7 (copper) |

| Maximum processed pipe diameter for punching | Φ40mm*1.5mm (copper) |

| Maximum machining wall thickness for punching | 1.50mm |

| Minimum spacing between two holes | 19 mm |

| Maximum machining length of workpieces | 2000mm |

| Processing efficiency (punching) | 4 sec /each hole |

| Processing efficiency (bending) | 3-4 sec /each bending |

| Processing and punching error | ≤0.2mm |

| Processable materials | Copper, iron, stainless steel, aluminum |

| Electronic control | Numerical control system |

| Punching method | Internal pressing |

| Operating method | Manual, automatic |

| Power supply | Three-phase 380V |

| Total power | 10KW |

| Hydraulic motor power | 3.7KW |

| Hydraulic system pressure | 3-7MPA |

| Machine dimension | 3400*1000*1300 |

| CNC control system | Shenzhen |

| Hydraulic solenoid valve | Taiwan |

| Oil pump | Taiwan |

| Sensor | Autonics Korea |

| Air switch and low-volt apparatus | Siemens\ IDEC |

| Servo motor and driver | Mitsubishi Japan |

| Lead screw | TBI |

| Speed reducer | Taiwan |

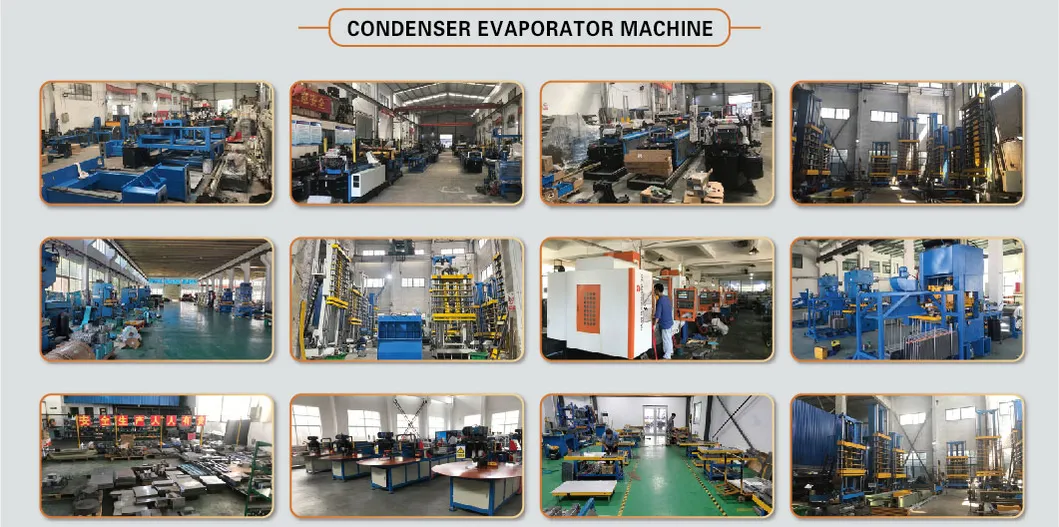

Wir, Ningbo Xin Chang Machinery Co., Ltd., sind ein professioneller Entwickler und Hersteller von Reibschweißmaschinen, Widerstandsschweißmaschinen und Wärmetauschergeräten. Unsere Fabrik ist seit mehr als 20 Jahren in dieser Branche tätig, wir haben mehr als 10 leitende Mechanik- und Elektrospezialisten und insgesamt mehr als 200 Mitarbeiter. Unsere Maschine ist in China berühmt. Wir verfügen über CCC-, ISO9001- und CE-Zertifikate.